by Barrie Wills, with acknowledgements to Stuart Craven, Nick Sutton‘s book The DeLorean Story, the Sunday Times newspaper, and the DeLorean Motor Company website.

In the fall of 1980, John Z. DeLorean was in Dunmurry for one of his ‘in and out’ day visits, and all seemed quiet, as everything at this stage by our standards, seemed to be going reasonably smoothly. Everyone in the company was working flat out.

The peace was broken when director of manufacturing George Broomfield, director of engineering administration and quality, Mike Loasby and I were asked to join John Z and managing director Charles K. Bennington in the boardroom. We arrived with hastily written crib sheets, from which we could update the chairman on our respective progress. John Z was at his most convivial when we opened the conference room door and filed in.

He went straight to the point and told us the American Express Christmas Mail Order Catalogue had the largest circulation of any across the US. How interesting, I recall thinking. He went on to astonish us all by announcing he had finalized a deal for its front cover to feature a picture of a gold DMC-12. That’s good, we thought. Then came the punchline: ‘ … and inside we will be offering to sell 100 24-carat gold-plated cars at $85,000 each to the first comers.’ We stared at each other in disbelief. It was not as if we hadn’t enough to do, without a side issue of this magnitude to account for. But this was for real, even though New York-based DeLorean PR chief Mike Knepper thought the idea came from John Z’s interior decorator Maur Dubin. John Z was not joking – the deal was done. The cars were to be delivered to the lucky buyers by October 1981.

My mind went back to my youth. I had grown up at the bottom of the hill leading to the Daimler factory in Radford, Coventry. I remembered the ‘jungle drums’ doing the rounds when I was about 13. Somehow, we local urchins got to know when the chairman of Daimler’s wife, Lady Norah Docker, was about to appear in her Daimler DK400 Coupe, complete with seats trimmed in natural zebra hide and gold-plated bright body fittings. We would congregate until it passed us. That car’s components were only 14-carat gold. Cheapskate!

Once the three of us had left the boardroom, we all agreed no one would be crazy enough to buy one. So we could get on with the job and wait for it to go away. But it didn’t. By the Spring of 1981 we were shocked to learn from John Z that two cars had been ordered – not 100, fortunately. In a way though two were as big a problem as would 100 have been as no-one had a clue whether stainless steel could be gold-plated successfully.

We also learned the front and rear fascias and road wheels were to be painted a ‘matching’ gold colour, and that specially-designed exhaust tips manufactured by trusted supplier Prescott Powell, wheel nuts, door hinges, rivets for the door seals, other visual small metal pressings, and the aluminium front DMC logo were required to be gold-plated too. Knowing it had been impossible to match a silver painted fascia with the normal grained stainless steel, an ‘executive decision’ was made to ask the fascia supplier Phoenix to paint three (including a spare set of course) to an acceptable contrast in line with the policy adopted for production cars. A deal was also negotiated with GKN Alloys for the painting of three sets of road wheels to a ‘gold’ colour to compliment the plated skin panels.

As the gold-plating of the grade 304 stainless steel was to be the most demanding element of the process, after I consulted with production purchasing manager Nick Sutton in the Coventry office, senior buyer Stuart Craven, the most technically-qualified of the Coventry purchasing team, was given the job of leading the project. He was supported by Len Nelson of quality engineering; Martin Mail, our new product planning manager; and George Fraser of material control manager Martin Graham‘s material handling team. Stuart undertook a review of gold-platers in the UK and mainland Europe, quickly finding out hardly any had the processing equipment capable of plating the size of panels in the DeLorean’s body shell. Very soon he focused his attention on the well-proven plating expertise of the large German chemical conglomerate Degussa.

Degussa’s payment terms demanded the gold itself should be paid for up-front. I swallowed hard, conferred with director of finance Joe Daly and financial controller David Adams, and agreed to pay the $45,000 that represented, at the same time as Nick Sutton’s team’s order was placed. Despite their impressive facilities, a larger purpose-built plating vat was required, estimated to cost $37,000. By comparison, the plating process itself represented a meagre $15,000. In view of the number of unknowns relating to the likelihood of success, Degussa went the whole hog and asked for a total (including ancillary costs) of $131,000 up front. All for three sets of panels and door assemblies, one each for the two cars bearing a selling price premium of $60,000 each, and a third in case anything went wrong and if available – as most did – to be held as spares in Irvine, California. The only concession we managed to negotiate was that of a refund for any gold left over in the vat after plating – small mercies – and a chance perhaps to make up for the nett loss (before labour and overhead costs at Dunmurry) of $11,000.

As Stuart got deeper into discussions with Degussa, it became clear they were more than sceptical about the likelihood of success. To Stuart’s shock they asked whether the plating could be carried out at Dunmurry to avoid damage to the panels after plating – with them providing the process know-how, the electrolyte solution, specialist platers and other processors. Stuart didn’t bother to consult Nick Sutton in Coventry or anyone in Dunmurry on that point as he knew how impractical that was, even if we had space to spare, which we hadn’t.

By late July, Degussa had successfully plated a sample piece of grade 304 stainless steel, small cropped samples of which were dispatched to Phoenix in Hamburg, Germany and GKN in Rochester, Kent, England for them both to commence the selection of appropriate complimentary shades of ‘gold’ paint, assisted by Martin Mail and – as it turned out – his wife Joan.

On August 20th, 1981 Stuart held a meeting in Germany with Degussa’s commercial and technical specialists Herrn Liebenow and Schettle. Even more concerns became apparent as it turned out Degussa’s previous experience had been in depositing much thinner coatings of 0.1 to 0.2 microns of gold, whereas our requirement demanded a far deeper coating of 2.5 microns. Also, Degussa simply could not guarantee an even deposit over the panels.

In turn, the more-than-nervous Degussa introduced Stuart to the facilities of their plating sub-contractors Holders, based in Lenningen, Baden-Württemberg, near Stuttgart. They promised they would have capacity available in September. That was the good news, further bad news was neither Degussa nor Holders were confident enough to accept responsibility for the quality of the finished products. Even more complications were disclosed. The size of the plating vat would have to be increased as would the amount of electrolyte needed; drainage holes would have to be carefully located in the door assemblies, from which the threaded inserts would have to be removed; and it would be down to DeLorean’s Len Nelson to make decisions on quality before and after plating. To avoid damage, Len and George specified that, once plated, the panels and door assemblies were to be shrink-wrapped in plastic sheeting and held in place by expanded foam supports before being packed in tri-wall containers.

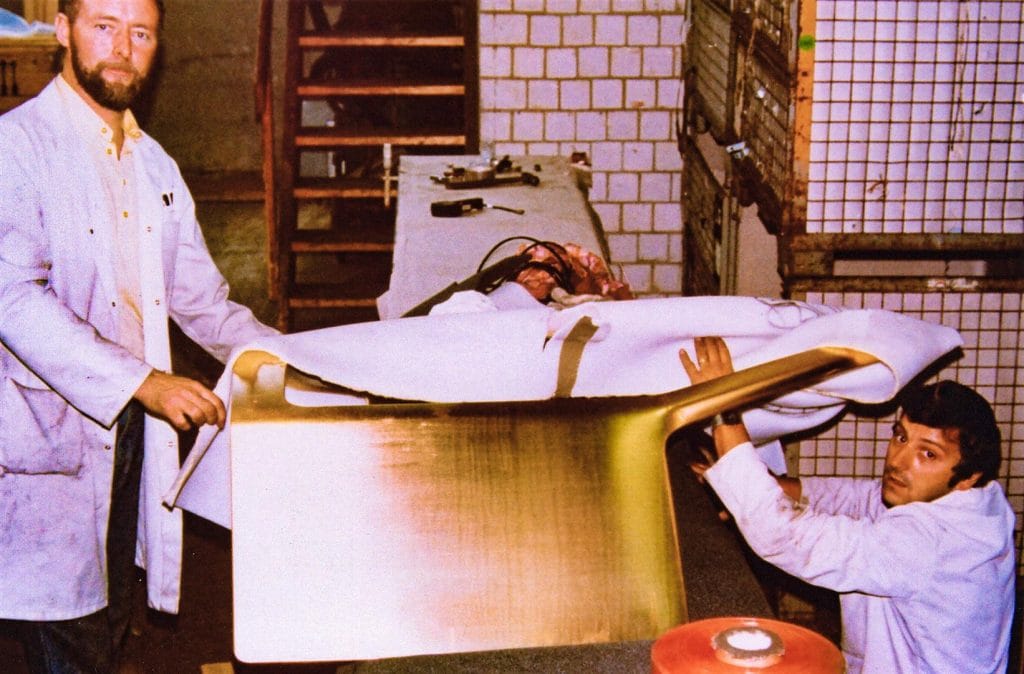

Stuart and the support team arrived at Holders on Tuesday, 15 September 1981 to discover the reason that date had been selected by the Germans was the plant was on vacation! Consequently, there was no local labour to assist but the ultra-careful unpacking and inspection went ahead regardless. The DeLorean team, therefore, set about the task unaided. Lacquer was painted on the inner surfaces of the panels, the smallest roof T-panels first, to prevent them from being gold-plated unnecessarily. Two days later, rear quarter panel assemblies and front fenders had been added to the completed stock of gold-plated roof T-panels.

Next came the doors. To their horror, the team found one door assembly had moved in transit, damaging a corner. Stuart rang Dunmurry to request an urgent replacement. Even by air-shipment that would not arrive before Saturday, the day by which the process of unpacking, cleaning, inspecting, lacquering, plating, inspecting and repacking had to be finished. An attempt to repair the damaged door failed. There was nothing other than to accept the spare ‘set’ would probably be less a door assembly – the least of concerns in the circumstances.

Friday’s task was the hood, the largest panel to be gold-plated. Its size meant each of the three had to be left in the vat longer to ensure the correct thickness of gold was applied to its centre. This ate up much-needed time required for plating the remaining five door assemblies, resulting in the plating of the fifth door having to be tackled on the final day – Saturday. Time was very much at a premium and Stuart was driven to the airport to collect the replacement door assembly in the hope there might still prove to be time available for it to be plated.

The air-freighted door had arrived at 1800 hours on the previous evening and there were no customs officials available at the weekend for clearance to be formalised before Monday – days too late! Seeing the carefully wrapped door assembly standing in the corner of the customs office, Stuart simply picked it up and walked out.

He returned to Holder’s plant just in time to see the fifth door plated. With time rapidly running out, the sixth assembly was simply cleaned, missing out the lacquering process, with the result the panels of this door assembly were gold-plated on the inner and outer panels. Towards the end of a very long day, packing of the doors was completed and all was ready for loading onto the truck for shipment to Dunmurry.

The next obstacle was that in Germany, trucks were not allowed to travel on roads over the weekend. Fortunately, this had been anticipated as the team had hired a refrigerated truck normally used for transporting fresh fruit – the one exception to the exclusion. Even then, the team was hoping there would be no inspection of the truck’s contents en-route through Germany. The climax of the team’s achievement was a frantic non-stop drive in the refrigerated truck through the night across Germany and France, by ferry into, and then across Britain, and finally into Northern Ireland by a second ferry. They arrived at the plant in Dunmurry in the early hours of Tuesday September 22nd, 1981 as Nick Sutton put it when he heard the news, ‘tired but happy’.

At the plant, the American Dick Kendall, supported by Alec Mackenzie, headed up a team of operators which then converted two offline cars into the gold-plated masterpieces; one with saddle tan cow (not zebra) hide trim, the other in black. Despite all the efforts in Germany to achieve three pairs of gold-plated doors, one was damaged in the build process. The build was undertaken in a specially-prepared, wired-off crib within the EVP building. Painter and handyman, Joe Murray (employee #65) blacked-out the windows to stop prying eyes and photographers from recording the action, although a number of official photographs were taken by Belfast photographer Esler Crawford under contract to DMCL. Each production operative assigned to work on the cars was provided with special passes along with overalls without zips, buttons, hooks or buckles – only velcro secured them. No rings or watches were allowed to be worn in the crib, which had 24-hour security under the direction of security chief Tony McDade.

On a bright, early October morning, under the bluest of blue skies – an Ulster rarity – the two cars were pushed outside the EVP building, steered by Stuart Craven, the hero of the piece. Under Dick’s supervision they had been constructed by a carefully selected, now very proud team of operatives. The cars looked magnificent, particularly under another rarity – the Ulster sun.

Those who worked on the gold cars received a certificate to that effect signed by John Z. DeLorean and new managing director Don Lander. Sadly, Coventry-based Stuart Craven and Martin Mail, and Dunmurry’s Len Nelson and George Frazer, who had all played such key roles in making the assembly work possible, were forgotten as the promoters of the certificate focused solely on the activity at Dunmurry. I did not know of the existence of the certificates for decades afterwards and I suspect George Broomfield and Mike Loasby were left equally in the dark. Had any of us known, we would have ensured the circulation was broadened to encompass all those involved in the complex exercise.

The two cars were duly shipped to the USA and customs clearance and onward transportation went smoothly. In an internal memo to Don Lander, sales and marketing vice-president CR ‘Dick’ Brown wrote, “The San Francisco unit was in the hands of the dealer on Friday, and delivery to the customer [Sherwood Marshall, an entrepreneur and former Royal Canadian Naval Officer] was made on Monday 12 October. The customer was delighted and he and his wife drove the car from the dealer through San Francisco traffic to his home in Walnut Grove, CA. The Texan customer [Roger Mize, president of Snyder National Bank in Snyder, Texas] has installed the unit in his bank and is very pleased with his car. His grand opening is on Thursday October 15th“.

There was one outstanding component at that stage – the DMC logos for the front grilles. Gold-plating aluminum had proven more difficult than expected. Three were flown to Stuart at the Coventry office for him to onward ship to Dick Brown in California. There was a pleasant surprise for Stuart – a fourth DMC logo for him to keep as a souvenir and at least compensate for the absence of the well-deserved certificate!

VIN 04301, an automatic transmission car with black interior trim, sat in a bullet-proof glass case in the lobby of Snyder National Bank for over 20 years before being loaned to the Petersen Automotive Museum in Los Angeles, California. VIN 04300, a manual transmission car with the first-ever set of saddle tan interior trim, is on loan from Sherwood Marshall to the William F. Harrah Exhibition at the National Automobile Museum in Reno, Nevada.

The third near-set of gold-plated stainless steel panels, door assemblies and other components were transferred to the parts warehouse in Irvine, under the care of national parts manager Leif Montin. They remained there until the financial difficulties of the winter of 1981-82. The eventual distressed-sale by DMC of the entire stock of cars and parts in the USA to Consolidated International of Columbus, Ohio, led to the gold-plated panels becoming their property.

The receivers of DMCL, Sir Kenneth Cork and Paul Shewell, were appointed in February 1982. After a further 500 cars had been completed at Dunmurry and a number of efforts had been made to save the business, Consolidated were brought onto the Dunmurry stage. The stock of finished cars in Northern Ireland were sold to Consolidated, and on Friday, 22 October 1982 Jeffrey Abrams, their operations manager, arrived on the scene.

The stock of original equipment parts in Dunmurry was then also sold by the receivers to Consolidated. This was containerised, shipped to Columbus, Ohio, under the direction of Leif Montin, who was contract-hired for the purpose, and joined company there with the former-Irvine stock, including the spare set of gold skin panels and associated components. Jeffrey Abrams had his eye on the spare set for planned modifications to what he termed ‘his car’. This, the last car ‘built’, was in fact a long-service product-development car specially prepared by Dunmurry’s chief engineer Peter Milner, supported by his superintendent/assistant Chris Bradley and their small team of mechanics.

On arrival in Columbus, another door was gold-plated under Consolidated’s supervision – unfortunately not to the carefully prepared process developed at Holders. As a result, the gold-plating appeared a totally different shade to the balance of the car set. That third set of door assemblies and skin panels, and a second set of saddle-tan trim from the parts stock in Irvine, were fitted to the ‘Milner-Bradley’ car in Columbus. Abrams was not allowed the personal-ownership he had planned and the car entered a public raffle as the so-called ‘last production car’, to which Abrams had applied the totally fictitious identification plate – VIN 20105. During the sale of the raffle tickets, the car was displayed outside the Columbus warehouse in which the parts had been stored.

Eventually, three decades after the gold-plated panels had been fitted in Columbus, in September 2013, that third car featured on the cover of a colour section of the British Sunday Times newspaper after it became a ‘barn find’ in the USA. It had surfaced in a remote part of the state of Maryland, owned by an octogenarian collector, named Carl Winters, who had kept it under a dust sheet in his garage since 1999. He claimed he bought the car after seeing it advertised in a newspaper. Since buying it, apart from the occasional display at local shopping centres, the gold-plated DeLorean had not moved and was in mint condition. Winters planned to sell it and with gold prices at a then-all-time high, along with the car’s rarity, advertised it for sale at $250,000. It is thought to remain unsold and now resides in a private collection in La Vale, Maryland.

More details at www.DeLoreanDirectory.com/deloreans/vin04301

Barrie Wills is the author of “John Z, the Delorean & Me: Tales from an Insider“, and “45+ Years Without John DeLorean“

Barrie Wills is the author of “John Z, the Delorean & Me: Tales from an Insider“, and “45+ Years Without John DeLorean“